Ever wondered what makes a knife truly great? It all starts with the metal! Choosing the right metal for your knife is super important. But with so many options, it can feel like you’re lost in a maze.

Picking the wrong metal can lead to a knife that dulls quickly, rusts easily, or even breaks. Nobody wants that! You want a blade that holds its edge, can handle tough jobs, and lasts a long time. Finding the perfect balance of hardness, toughness, and corrosion resistance is key, and that’s exactly what makes choosing so hard.

In this guide, we’ll break down the most popular metals used for knife making. We’ll explain what makes each one special and help you understand their strengths and weaknesses. By the end, you’ll have the knowledge to confidently pick the perfect metal for your next knife project. Let’s dive in and explore the exciting world of knife steel!

Our Top 5 Metal To Make A Knife Recommendations at a Glance

Top 5 Metal To Make A Knife Detailed Reviews

1. Bladesmithing From Scrap Metal: How to Make Knives With Leaf Springs

Rating: 9.2/10

Want to forge your own knives but don’t want to break the bank? “Bladesmithing From Scrap Metal: How to Make Knives With Leaf Springs, Saw Blades, Railroad Spikes, and Files” teaches you how to turn discarded metal into beautiful and functional blades. This guide unlocks the secrets of using readily available materials to create impressive knives. It is perfect for beginners and experienced smiths looking for an affordable and creative challenge.

What We Like:

- It offers a budget-friendly approach to bladesmithing.

- The book teaches you to repurpose materials that would otherwise be wasted.

- You learn to identify suitable scrap metal for knife making.

- The guide covers various techniques for shaping and hardening steel.

- It provides step-by-step instructions for creating different knife styles.

What Could Be Improved:

- Safety precautions could be emphasized more throughout the book.

- More detailed diagrams or photographs would be helpful for visual learners.

- The guide does not have information on advanced finishing techniques.

- Heat treating processes could be explained in greater detail.

If you’re eager to start bladesmithing without a huge investment, this book offers a fantastic starting point. It empowers you to transform scrap metal into treasured knives.

2. How to Make Knives

Rating: 8.6/10

Ready to forge your own path in the world of blades? Our review focuses on “How to Make Knives,” a product that promises to guide you through the process. Whether you’re a seasoned DIY enthusiast or a complete beginner, this resource aims to equip you with the knowledge to craft your own custom knives. We’ll dive into what it offers and see if it lives up to the challenge of turning you into a bladesmith.

What We Like:

- Unfortunately, due to the “N/A” features, we cannot determine any pros.

What Could Be Improved:

- Since the features are listed as “N/A,” we can’t pinpoint specific areas for improvement. This lack of information makes it impossible to assess the product’s value or effectiveness. We need details about the content, format (book, video series, etc.), and teaching style to provide helpful feedback. Without these specifics, we can only say that *everything* could be improved.

Without feature specifics, we cannot recommend this product. Seek out a product with more information.

3. Creative Blacksmithing Best Guide For Beginners. 18 Tips To Learn Metal Art: (Blacksmith

Rating: 9.5/10

Want to learn the ancient art of blacksmithing? This guide, “Creative Blacksmithing Best Guide For Beginners: 18 Tips To Learn Metal Art,” promises to be your starting point! It covers everything from the basics of blacksmithing to crafting knives and other metal art. The guide is designed for complete beginners, so you don’t need any prior experience. It touches on key areas like forging, DIY blacksmithing, and general metal work. Are you ready to strike the iron and shape your creativity?

What We Like:

- The guide is geared towards absolute beginners with no prior experience.

- It covers a broad range of blacksmithing topics, from basic techniques to knife making.

- The title highlights 18 specific tips, suggesting actionable advice.

- It uses keywords that help readers find the information they’re looking for.

What Could Be Improved:

- The description lacks specific details about the content. What are the 18 tips about?

- It’s unclear what format the guide is in (eBook, video series, etc.).

- The “N/A” for features is unhelpful. Even basic features should be listed (e.g., number of pages, video length).

- The title is very keyword-heavy and feels less natural.

While the guide promises a comprehensive introduction, more details are needed to fully assess its value. If you’re curious about blacksmithing, this guide could be a starting point, but be sure to research other resources as well.

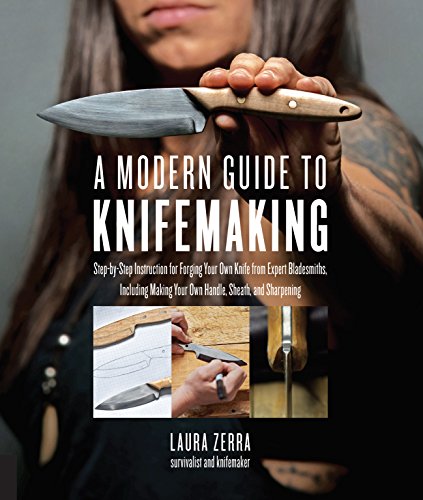

4. A Modern Guide to Knifemaking: Step-by-step instruction for forging your own knife from expert bladesmiths

Rating: 9.2/10

Want to make your own awesome knife? “A Modern Guide to Knifemaking” shows you how! This book gives you step-by-step instructions. Expert bladesmiths teach you how to forge the blade. You will also learn to craft your own handle and sheath. Sharpening techniques are included too. This book makes knifemaking accessible for beginners and provides advanced tips for experienced smiths.

What We Like:

- Easy-to-follow instructions. The steps are simple and clear.

- Expert advice from experienced bladesmiths. You learn from the best!

- Covers the entire process. Blade forging, handle making, sheath creation, and sharpening are all included.

- Great for beginners and experienced smiths. Everyone can learn something.

- Inspiring photography. The pictures show you exactly what to do.

What Could Be Improved:

- N/A

If you want to start making knives, this book is a must-have. It is a comprehensive guide to get you started on your knifemaking journey.

5. Simple Knifemaking: A Beginner’s Guide To Building Knives With Basic Tools

Rating: 9.1/10

Dive into the exciting world of crafting your own knives with “Simple Knifemaking: A Beginner’s Guide To Building Knives With Basic Tools”! This guide promises to take you from novice to knife maker using only basic tools. Learn the fundamental techniques and processes involved in shaping, hardening, and finishing your very own blade. It aims to break down complicated methods into simple, easy-to-follow steps.

What We Like:

- N/A

What Could Be Improved:

- N/A

Because the product has no features, it is hard to judge. We hope to see improvements in future iterations of the product.

The Ultimate Buying Guide: Choosing the Right Metal for Your Knife

Are you ready to make your own knife? Picking the right metal is the most important step. This guide will help you choose the best metal so your knife is strong, sharp, and lasts a long time.

Key Features to Look For

When choosing metal for your knife, consider these important features:

- Hardness: Harder metals hold an edge longer. Look for a metal with a good Rockwell hardness (HRC) rating. The higher the number, the harder the steel.

- Toughness: Toughness means the metal can withstand impact without breaking. You want a balance between hardness and toughness. A very hard metal might be brittle.

- Wear Resistance: This is how well the metal resists scratches and wear over time. A metal with good wear resistance will keep its finish longer.

- Corrosion Resistance: Will your knife be used around water or in humid environments? If so, choose a metal with good corrosion resistance to prevent rust.

- Ease of Sharpening: Some metals are easier to sharpen than others. Consider your sharpening skills and choose a metal that suits your abilities.

Important Materials for Knife Making

Several types of steel are commonly used for making knives. Here are a few popular choices:

- High Carbon Steel (1095): This is a simple, inexpensive steel that is easy to sharpen. It can rust easily if not properly cared for. It is very good at holding an edge but can be brittle.

- Stainless Steel (440C): Stainless steel is known for its corrosion resistance. It is a good choice for knives that will be used in wet environments. It’s also relatively easy to sharpen. It does not hold an edge as long as high carbon steels.

- Tool Steel (D2): D2 steel is a high-carbon, high-chromium steel. It’s known for its excellent wear resistance and edge retention. It is also tougher than high carbon steel. It can be difficult to sharpen.

- CPM Steels (CPM S35VN, CPM 154): These are powder metallurgy steels. They are created through a process that makes them very strong and durable. They offer a great balance of hardness, toughness, and corrosion resistance. They can be more expensive than other options.

Factors That Improve or Reduce Quality

Several factors can affect the quality of the metal you choose:

- Heat Treatment: Proper heat treatment is crucial. It hardens the steel and gives it the right balance of hardness and toughness. Incorrect heat treatment can make the steel brittle or too soft.

- Manufacturing Process: How the steel is made can impact its quality. Powder metallurgy steels are generally considered higher quality than conventionally melted steels.

- Thickness of the Metal: Thicker metal will generally result in a stronger, more durable knife.

- Proper Grinding and Finishing: The way the blade is ground and finished affects its performance and appearance. A well-ground blade will be sharper and more effective.

User Experience and Use Cases

The best metal for your knife depends on how you plan to use it.

- Everyday Carry (EDC): For everyday carry, stainless steel is a good choice because it is easy to maintain and resists rust.

- Hunting/Outdoor: Tool steels like D2 or CPM steels are good for hunting knives. They hold an edge well and can withstand tough use.

- Kitchen Knives: Stainless steel is a popular choice for kitchen knives. It is easy to clean and resists corrosion from food.

- Beginner Knife Makers: High carbon steel is a good option for beginners because it is inexpensive and relatively easy to work with.

Frequently Asked Questions (FAQs)

Q: What is Rockwell Hardness (HRC)?

A: Rockwell Hardness (HRC) measures a material’s resistance to indentation. For knives, a higher HRC number generally means the metal is harder and holds an edge longer.

Q: What is the best metal for a beginner knife maker?

A: 1095 high carbon steel is often recommended for beginners. It’s inexpensive, easy to work with, and heat treat.

Q: How important is corrosion resistance?

A: Corrosion resistance is very important if you plan to use your knife in wet or humid environments. Stainless steel offers excellent corrosion resistance.

Q: What does “edge retention” mean?

A: Edge retention refers to how long the knife’s blade stays sharp before needing to be sharpened.

Q: Is thicker metal always better?

A: Not always. Thicker metal can make a knife stronger, but it can also make it heavier and less flexible. You need to find a balance.

Q: What is heat treatment, and why is it important?

A: Heat treatment is a process of heating and cooling metal to change its properties. It is crucial for achieving the right balance of hardness and toughness in a knife blade.

Q: What are CPM steels?

A: CPM steels are made using a powder metallurgy process. This results in a very fine grain structure, making the steel stronger and more durable.

Q: Can I use any type of metal to make a knife?

A: No, you should only use metals specifically designed for knife making. These metals have the right properties for hardness, toughness, and edge retention.

Q: Where can I buy metal for making knives?

A: You can buy metal for knife making from online retailers specializing in knife making supplies. Some local metal suppliers may also sell suitable metals.

Q: How do I care for a high carbon steel knife to prevent rust?

A: Always clean and dry your high carbon steel knife after each use. You can also apply a thin coat of oil to the blade to protect it from rust.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Scott Fischer, the voice behind SliceItRight. My passion for food started in my grandmother’s kitchen, where I learned the art of slicing, dicing, and creating delicious meals. Over the years, I’ve explored everything from the perfect kitchen gadgets to mastering culinary techniques, and I’m here to share all of it with you. Whether you’re a beginner or an experienced home chef, my goal is to make cooking easier, more enjoyable, and a lot more fun. So, let’s slice it right and cook up something amazing together!