Imagine holding a perfectly balanced knife, its blade sharp enough to slice through anything. What makes a knife truly great? It all starts with the metal.

Choosing the right metal for knife making can feel like navigating a maze. There are so many types, each with its own strengths and weaknesses. Some metals are super hard but can be brittle, meaning they might chip easily. Others are tough and won’t break, but they might not hold an edge as long. This makes picking the wrong metal a real problem for anyone wanting to make a good knife.

In this post, we’ll explore the exciting world of knife-making metals. You’ll learn what makes certain metals better for blades and how to avoid common mistakes. By the end, you’ll understand which metals will help you create knives that are not only sharp but also strong and reliable.

Our Top 5 Metal For Knife Making Recommendations at a Glance

Top 5 Metal For Knife Making Detailed Reviews

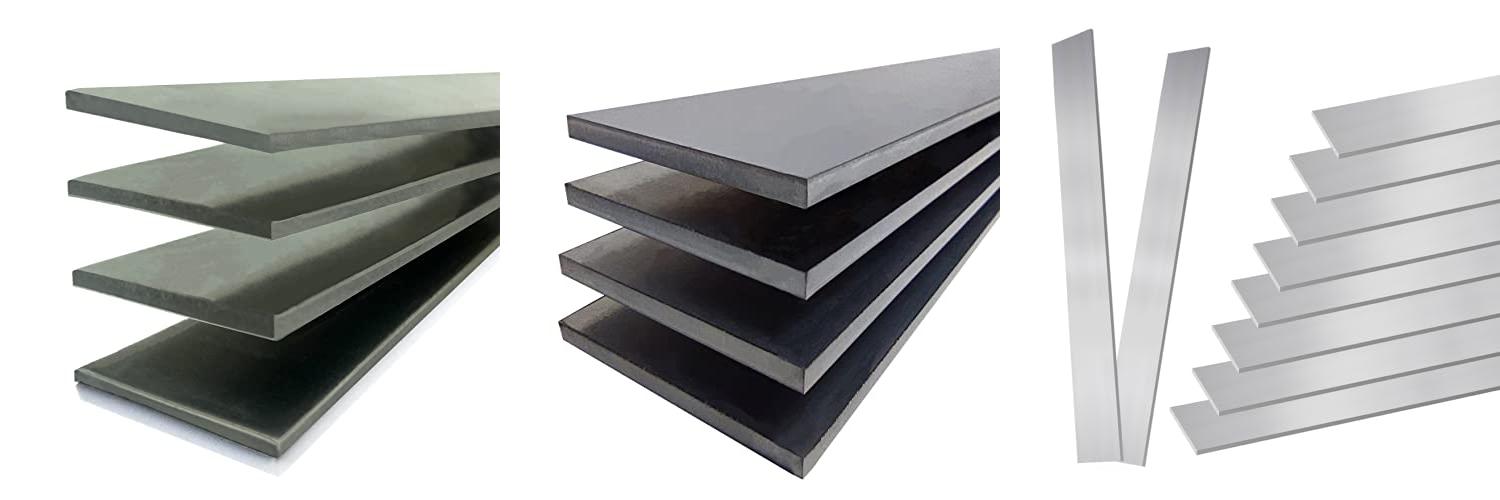

1. 1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel

Rating: 8.9/10

Unleash your inner craftsman with this 1095 Steel Flat Stock, designed specifically for knife making and DIY projects. This pack of four annealed, high-carbon steel bars provides the perfect foundation for creating durable and sharp blades.

What We Like:

- Superior Material: Made from 1095 steel, the highest carbon grade, these bars offer excellent heat treatment results. This means your finished blades will be tough and hold a sharp edge.

- Ready for Work: The cold-rolled and annealed finish saves you valuable time. It enhances the steel’s properties, meaning less sanding and easier shaping for your projects.

- Built to Last: The steel boasts super toughness and grindability. It’s ideal for crafting knives, hand tools, and even spacers for various applications.

- Careful Packaging: Each pack is hand-packed with three layers of rust-proof protection – oil, paper, and bubble wrap. This ensures your steel arrives in perfect condition, free from rust or damage.

- Convenient Size: The dimensions of 12″ x 1.5″ x 0.12″ are practical for a wide range of DIY blade designs. You get four of these useful bars in one package.

What Could Be Improved:

- Beginner Learning Curve: While great for DIY, working with high-carbon steel requires some knowledge of heat treating and shaping techniques. Newcomers might need extra research.

This 1095 steel flat stock is an excellent choice for anyone serious about making their own blades. Its quality and preparation make it a reliable material for your crafting adventures.

2. 4 Pack 1095 Steel for Knife Making – 12″x1.5″x0.12″ Annealed High Carbon Tool Steel Blanks

Rating: 8.5/10

Looking to craft your own custom knives? This 4-pack of 1095 steel flat stock is designed for serious DIY enthusiasts and aspiring bladesmiths. Each bar measures 12 inches long, 1.5 inches wide, and 0.12 inches thick, offering ample material for multiple projects. This high-carbon tool steel is known for its excellent toughness and ease of grinding, making it a favorite among professional knife makers.

What We Like:

- BEST CHOICE FOR YOUR KNIFE: 1095 steel is the perfect material for making knives. Many famous knife companies choose it. Its super toughness and easy grinding make it great for your handmade knives.

- COLD ROLLED & ANNEALED: The steel is annealed. This makes it easier to work with. You can process the steel easily. This saves you time and grinding belts.

- SPECIFICATIONS: You get four 1095 Steel Bar Stock pieces. Each bar is 12″ x 1.5″ x 0.12″. This is plenty of steel for your custom knife projects.

- PERFECT PACKAGING: The steel is protected with three layers. It has rust-proof oil, rust-proof paper, and bubble bags. This keeps your steel from rusting or getting damaged.

- AFTER-SALES SERVICE: Your happiness is important. If the steel doesn’t meet your needs, they will fix it.

What Could Be Improved:

- While the steel is annealed for better machinability, it is still a high-carbon steel and will require proper techniques and tools for shaping and heat treatment.

- The description focuses heavily on knife making, but it could mention other potential DIY projects where this type of steel might be useful.

This 1095 steel offers a fantastic starting point for your knife-making adventures. With its quality and thoughtful packaging, it’s a solid investment for any DIY project.

3. 1084 Steel Flat Stock Cold Rolled Carbon Steel Bar for Knife Making 12″x1.5″x 1/8″(10 Packs)

Rating: 9.5/10

Are you ready to craft your own amazing knives? This 1084 Steel Flat Stock is just what you need! It’s a pack of ten bars, each 12 inches long, 1.5 inches wide, and 1/8 inch thick. This steel is made for knife making, giving you strong, tough blades.

What We Like:

- Great Material: Made from 1084 high carbon steel. This steel is really strong and springs back well. It’s a flat steel plate, perfect for shaping.

- Carefully Packaged: Each bar comes wrapped in rust-proof paper and bubble bags. This keeps your steel safe from damage during shipping.

- Precise and Strong: The steel is cold rolled and annealed. This means it has a very exact thickness. It also has better strength and is easier to work with. It won’t bend easily and has a smooth finish.

- Good Value Pack: You get ten packs, which is a lot of material for your knife-making projects.

What Could Be Improved:

- Learning Curve: 1084 steel is a great material, but it does require specific heat treating. Beginners might need to do some extra research to get the best results.

- Shipping Weight: Since it’s steel and you get ten packs, the package can be a bit heavy.

This 1084 steel is a fantastic choice for anyone serious about making their own knives. You get quality material that’s ready for your creative touch.

4. SALUINOKI 4pcs 1095 Steel Flat Stock for Knife Making (12×1.5×0.12 inch) High Carbon Steel Blank Bar Forge Steel for Blacksmithing Forging

Rating: 9.1/10

If you’re looking to craft your own knives or get into blacksmithing, the SALUINOKI 4pcs 1095 Steel Flat Stock is a solid choice. This package gives you four pieces of 1095 steel, each measuring 12 inches long, 1.5 inches wide, and 0.12 inches thick. SALUINOKI specializes in steel for making knives, so they know their stuff. This steel is great for beginners who want to try forging and blade making.

What We Like:

- It comes in a pack of four, so you get plenty of material to practice with.

- The steel is specifically designed for knife making, making it a good starting point.

- The edges are polished to be blunt, which helps keep you safe while you work.

- SALUINOKI offers other types of steel and metal, so you can find different materials from them.

- The size is convenient for many knife projects.

What Could Be Improved:

- For very advanced projects, some users might prefer different steel types.

- The thickness might be a little thin for some heavy-duty applications.

This steel is a great way to start your journey into knife making. It provides a good balance of quality and safety for aspiring bladesmiths.

5. Patriot Steel 5160 High Carbon Knife Making & Forging Steel – Hot Rolled Steel for Knife Making Supplies – USA-Milled Excellence for Pros & Hobbyists – 1.25″ wide

Rating: 9.1/10

Patriot Steel 5160 High Carbon Knife Making & Forging Steel is a top-notch material for anyone serious about making knives. This hot-rolled steel is made right here in the USA, ensuring excellent quality for both pros and folks just starting out. Each pack comes with four pieces, each 1.25 inches wide, 0.25 inches thick, and 12 inches long, making it a great value for your projects.

What We Like:

- Exceptional Quality: It’s made from 5160 steel in the USA, meeting high standards for great performance.

- Reliable Consistency: Small batches and strict checks mean you get the same great steel every time.

- Versatile for All Skill Levels: Perfect for both expert knife makers and hobbyists.

- Trustworthy American Craftsmanship: Unlike many others, Patriot Steel is proudly made in the USA, not China.

What Could Be Improved:

- Availability: While the quality is fantastic, sometimes demand can make it hard to get your hands on.

- Learning Curve: For absolute beginners, understanding how to work with high-carbon steel might take some practice.

If you want reliable, high-quality steel for your knife-making adventures, Patriot Steel is a solid choice. You can count on its American-made excellence.

Choosing the Right Metal for Your Knife Making Project

Q: What are the most important things to consider when buying metal for knife making?

A: When you buy metal for making knives, you need to think about what you want your knife to do. Do you want it to be super sharp and hold its edge for a long time? Do you need it to be tough and not break easily? The metal you choose will decide all of this.

Key Features to Look For:

1. Hardness:

Hardness tells you how well the metal resists scratching and wear. A harder metal will stay sharp longer. Think of it like a sharp pencil – a harder lead will write more cleanly for a longer time.

2. Toughness:

Toughness is how well the metal can handle being hit or bent without breaking. A tough knife is less likely to chip or snap. Imagine a strong stick versus a brittle twig. You want the strong stick for your knife.

3. Edge Retention:

This is how long your knife’s sharp edge lasts. Metals with good edge retention stay sharp for many uses. It’s like a good quality razor blade that stays sharp after several shaves.

4. Corrosion Resistance:

Some metals can rust or get stained easily. Corrosion resistance means the metal fights off rust. Stainless steel is a good example of a metal with high corrosion resistance.

Important Materials:

There are many types of metal used for knives, but here are some common ones:

- High Carbon Steel: This metal gets very hard and holds a sharp edge well. It’s great for knives that need to be very sharp, but it can rust if you don’t take care of it.

- Stainless Steel: Stainless steel has chromium in it, which helps it resist rust. It’s a good all-around choice for many knives because it’s strong and doesn’t rust easily.

- Tool Steel: This is a very tough and hard metal. It’s used for tools like drill bits and also for high-quality knives that need to be very durable.

- Damascus Steel: This is a special kind of steel made by layering different types of steel and folding them. It looks beautiful and can be very strong and sharp.

Factors That Improve or Reduce Quality:

Factors That Improve Quality:

- Proper Heat Treatment: This is a special heating and cooling process that makes the metal stronger and harder. It’s very important for a good knife.

- Good Design: The shape and thickness of the metal blank (the rough shape of the knife before sharpening) also matter. A well-designed blank will make a better knife.

- Cleanliness of the Metal: Pure metal with no extra bits in it will make a stronger knife.

Factors That Reduce Quality:

- Poor Heat Treatment: If the metal is heated or cooled incorrectly, it can become brittle or not hold an edge.

- Impurities in the Metal: Small pieces of other things in the metal can make it weak.

- Using the Wrong Metal for the Job: If you need a tough knife for chopping, using a metal that’s too brittle won’t work well.

User Experience and Use Cases:

The metal you choose will change how you use your knife. A knife made from high carbon steel will be very sharp, perfect for slicing vegetables or fine carving. You’ll need to wipe it dry after use to prevent rust.

A knife made from stainless steel is great for outdoor activities like camping or fishing because it won’t rust if it gets wet. It’s also good for everyday kitchen tasks.

If you’re making a knife for heavy-duty work, like chopping wood or tough materials, you’ll want a metal that is both hard and tough, like some tool steels. These knives can handle a lot of stress.

Think about what you will do with your knife. This will help you pick the metal that is best for you.

Frequently Asked Questions (FAQ):

Q: Is stainless steel always better than carbon steel?

A: Not always. Stainless steel resists rust better, but high carbon steel can often get sharper and hold its edge longer if treated properly.

Q: Can I use any metal to make a knife?

A: While you can shape many metals, not all will be suitable for making a functional knife that can be sharpened and hold an edge. You need metal with the right properties.

Q: How does the thickness of the metal affect the knife?

A: Thicker metal can make a stronger, more robust knife, but it might be heavier. Thinner metal can make a lighter, more agile knife, but it might be less durable.

Q: What is “temper” in knife making?

A: Tempering is part of the heat treatment process. It reduces brittleness in the hardened steel, making the knife tougher without losing too much hardness.

Q: Is Damascus steel good for everyday use?

A: Damascus steel can be excellent for everyday use, offering a good balance of sharpness, edge retention, and toughness, plus it looks beautiful.

Q: How do I know if the metal I bought is good quality?

A: Reputable suppliers will clearly label the type of steel. Reading reviews and understanding the properties of different steels will help you judge quality.

Q: Does the color of the metal matter?

A: The color of the raw metal doesn’t directly indicate its quality for knife making. The chemical composition and how it’s treated are what matter most.

Q: What is the best metal for a beginner knife maker?

A: For beginners, high carbon steel or a good quality stainless steel are often recommended because they are forgiving and widely available.

Q: How important is the grain structure of the metal?

A: The grain structure, which is how the metal’s crystals are arranged, is very important. A fine, uniform grain structure usually leads to a stronger and sharper blade.

Q: Can I make a knife from an old file?

A: Yes, old files are often made from high carbon steel, making them a popular material for DIY knife making. They need to be properly annealed, shaped, hardened, and tempered.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Scott Fischer, the voice behind SliceItRight. My passion for food started in my grandmother’s kitchen, where I learned the art of slicing, dicing, and creating delicious meals. Over the years, I’ve explored everything from the perfect kitchen gadgets to mastering culinary techniques, and I’m here to share all of it with you. Whether you’re a beginner or an experienced home chef, my goal is to make cooking easier, more enjoyable, and a lot more fun. So, let’s slice it right and cook up something amazing together!