Imagine holding a perfectly balanced knife, its edge slicing through materials with effortless grace. What makes that possible? It all starts with the metal. For anyone drawn to the craft of knife making, the metal is the heart of the blade, and choosing the right one can feel like navigating a maze.

The truth is, picking the wrong metal can lead to frustrating results. Will it hold an edge? Will it be too brittle and chip easily, or too soft and bend? These are the burning questions that keep aspiring bladesmiths up at night. The vast array of steels, each with its own strengths and weaknesses, can be overwhelming, leaving you wondering where to even begin.

But fear not! This post is your compass. We’ll break down the essential qualities of knife-making metals, helping you understand what makes each one tick. By the end, you’ll have a clearer picture of which metals best suit your needs and projects, empowering you to create knives that are not only beautiful but also incredibly functional.

Our Top 5 Knife Making Metal Recommendations at a Glance

Top 5 Knife Making Metal Detailed Reviews

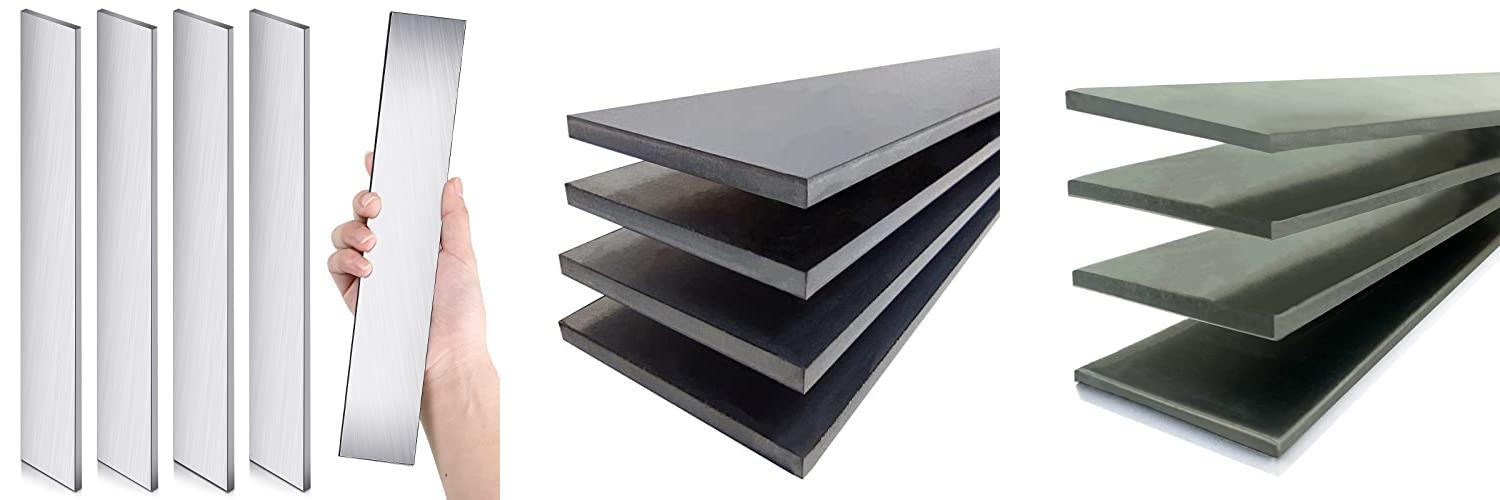

1. Ferraycle 11.5”x1.57”x0.06” 15N20 Steel Flat Stock Bar High Contrast Blade Billets Blanks Annealed High Carbon Steel Barstock for Hobbyist Use Making Forging Carbon Damascus Knives DIY(4 Pieces)

Rating: 9.2/10

Unleash your inner bladesmith with the Ferraycle 15N20 Steel Flat Stock Bar. This 4-piece set offers hobbyists the perfect material for crafting unique Damascus knives and other DIY projects. The 15N20 steel is known for its bright finish and resistance to wear and acids, making it a fantastic choice for creating beautiful, high-contrast blades when paired with higher carbon steels like 1095. Each bar is annealed, meaning it’s softened and easier to work with, perfect for beginners and experienced makers alike.

What We Like:

- Adequate Quantity: You get 4 pieces, which is plenty for several projects.

- Suitable Size: The dimensions (11.5″ x 1.57″ x 0.06″) are just right for making knives.

- Quality Steel: 15N20 is a durable, wear-resistant steel that’s great for knife making.

- Widely Applicable: It’s good for knives, hand tools, and more.

- High Contrast Potential: Works well with other steels to create striking Damascus patterns.

What Could Be Improved:

- Polishing for Etching: You might need to polish the surface well for the best etching results to see the contrast.

This Ferraycle steel is a solid foundation for your knife-making adventures. It provides the quality and quantity needed to bring your creative knife designs to life.

2. 4 Pack 1095 Steel for Knife Making – 12″x1.5″x0.12″ Annealed High Carbon Tool Steel Blanks

Rating: 8.6/10

Ready to craft your own amazing knives? This 4 Pack of 1095 Steel for Knife Making is a fantastic starting point. Each bar is 12 inches long, 1.5 inches wide, and 0.12 inches thick. This high-carbon steel is a favorite among knife makers because it’s tough and grinds well. It’s perfect for your DIY projects and creating custom blades that are built to last. You get four of these precision-ground flat stock bars in each package, so you have plenty to work with.

What We Like:

- This 1095 steel is a top choice for making knives. Many big knife companies use it.

- The steel is cold-rolled and annealed. This means it’s easier to work with, saving you time and effort.

- You get four good-sized steel bars. This is enough to make several knives or other cool projects.

- The steel is protected with three layers of rust-proof packaging. This keeps it safe and sound during shipping.

- The company stands behind its product. They promise to make things right if you’re not happy.

What Could Be Improved:

- While the steel is annealed for easier machining, high-carbon steel still requires proper tools and techniques to work with effectively. Beginners might find it challenging.

- The thickness of 0.12 inches is good for many knives, but some specialized knife designs might require thicker or thinner stock.

This 1095 steel pack offers great value for aspiring bladesmiths. It provides the quality material needed to bring your knife-making visions to life.

3. 1095 Steel Flat Stock for Knife Making-Annealed High Carbon Steel

Rating: 9.2/10

Get ready to craft your next masterpiece with this 1095 Steel Flat Stock! This pack comes with four pieces of high-quality, annealed 1095 steel, ready for your knife-making projects. Each bar measures 12 inches long, 1.5 inches wide, and 0.12 inches thick. This steel is known for its super toughness and how easily it grinds, making it ideal for DIY blades, knives, and hand tools. You can even use it for spacers!

What We Like:

- High Carbon Content: 1095 is the top-grade carbon steel. This means your finished blades will heat treat really well.

- Easy to Work With: The steel is cold rolled and annealed. This saves you time on sanding and makes it easier to shape.

- Great for DIY: The toughness and grindability are perfect for anyone making their own knives or tools by hand.

- Secure Packaging: The bars are well-protected with three layers of rust-proof packaging. This keeps them safe from rust and damage during shipping.

- Good Value: You get four good-sized pieces of quality steel for your projects.

What Could Be Improved:

- Thickness Consistency: While generally good, some users noted very minor variations in thickness across the batch.

- Annealing Softness: While annealed for easier work, some users might prefer an even softer state for initial rough shaping.

This 1095 steel flat stock is a fantastic choice for hobbyists and experienced makers alike. It provides a great base for creating durable and sharp tools.

4. Patriot Steel 5160 High Carbon Knife Making & Forging Steel – Hot Rolled Steel for Knife Making Supplies – USA-Milled Excellence for Pros & Hobbyists – 1.25″ wide

Rating: 9.3/10

Unleash your inner bladesmith with Patriot Steel’s 5160 High Carbon Knife Making & Forging Steel. This hot-rolled steel is your ticket to creating exceptional knives, whether you’re a seasoned pro or just starting your journey. Each pack comes with four pieces, measuring 1.25 inches wide, 0.25 inches thick, and 12 inches long, giving you plenty of material to work with.

What We Like:

- Exceptional Quality: Made in the USA, this 5160 steel is built to last and perform.

- Reliable Consistency: Small batch production means you get the same great quality every time.

- Versatile for All: Perfect for both professional knife makers and weekend hobbyists.

- American Craftsmanship: Proudly manufactured in the USA, ensuring authenticity and top-notch quality.

What Could Be Improved:

- The 12-inch length might limit very large knife projects for some users.

- While consistent, the price point may be a consideration for those on a very tight budget.

If you’re serious about knife making, Patriot Steel offers a reliable and high-quality foundation for your creations. Trust in American-made excellence for your next project.

5. SALUINOKI 4pcs 1095 Steel Flat Stock for Knife Making (12×1.5×0.12 inch) High Carbon Steel Blank Bar Forge Steel for Blacksmithing Forging

Rating: 9.4/10

Are you ready to craft your own blades? The SALUINOKI 4pcs 1095 Steel Flat Stock is here to help! This set comes with four pieces of high-quality 1095 steel, perfect for anyone interested in blacksmithing and knife making. Whether you’re a seasoned bladesmith or just starting out, these steel bars are a fantastic choice. SALUINOKI is known for providing excellent materials like 1084, 15N20, and 80CRV2 steel. They also offer aluminum and stainless steel sheets. You can find a variety of metals from SALUINOKI for all your crafting needs.

What We Like:

- Great for beginners and experienced crafters.

- The steel is a good size at 12×1.5×0.12 inches.

- Each piece has a polished, non-sharp edge, making it safer to handle.

- SALUINOKI offers a good selection of knife-making steels.

What Could Be Improved:

- The thickness of 0.12 inches might be a bit thin for some heavy-duty forging projects.

- More detailed information on the specific heat treatment properties could be helpful for advanced users.

This SALUINOKI steel set is a solid starting point for your knife-making journey. It provides the quality material you need to create impressive blades.

Choosing the Right Metal for Your Knife: A Beginner’s Guide

Making your own knife can be a rewarding hobby. It lets you create a tool that’s perfectly suited to your needs. But before you start, you need to pick the right metal. The metal you choose affects how sharp your knife can get, how tough it is, and how easy it is to work with. This guide will help you understand what to look for.

Key Features to Look For

When you’re picking metal for a knife, think about these important things:

1. Hardness

Hardness tells you how well a metal can hold a sharp edge. A harder metal will stay sharp longer. However, very hard metals can be brittle, meaning they might chip or break easily. You want a good balance.

2. Toughness

Toughness is the metal’s ability to resist breaking or chipping when it’s used. A tough knife can handle tough jobs without damage. This is super important for knives you’ll use a lot.

3. Corrosion Resistance

Some metals rust or corrode over time. If you want a knife that stays looking good and doesn’t need constant care, look for metal that resists rust. Stainless steel is known for this.

4. Ease of Sharpening

Even the hardest metal will get dull eventually. You’ll need to sharpen your knife. Some metals are easier to sharpen than others. If you’re new to knife making, starting with an easier-to-sharpen metal is a good idea.

Important Materials

There are two main types of metal used for knife making:

1. Carbon Steel

Carbon steel is a popular choice for knife makers. It has a good amount of carbon, which makes it very hard and able to hold a sharp edge. It’s also relatively easy to sharpen. However, carbon steel can rust if not cared for properly. You’ll need to oil it to keep it from rusting.

- Examples: 1075, 1095, O1 Tool Steel

2. Stainless Steel

Stainless steel contains chromium. This chromium helps it resist rust and corrosion. Stainless steel is a great option if you want a low-maintenance knife. Some stainless steels can be harder to sharpen than carbon steels, but modern stainless steels offer great performance.

- Examples: 440C, VG-10, D2

Factors That Improve or Reduce Quality

The way metal is made and treated affects its quality:

1. Heat Treatment

Heat treatment is a process that makes metal harder and tougher. It involves heating the metal and then cooling it in a specific way. Good heat treatment is crucial for a high-quality knife. Poor heat treatment can make even good metal brittle or soft.

2. Alloying Elements

Adding other elements to steel, like chromium, nickel, or vanadium, can change its properties. These elements can improve hardness, toughness, or corrosion resistance. For example, chromium makes steel stainless.

3. Manufacturing Process

How the steel is made in the first place matters. Steel made with better processes tends to have fewer impurities, which makes it stronger and more reliable.

User Experience and Use Cases

The metal you choose should match how you plan to use your knife:

1. Everyday Carry (EDC) Knives

For a knife you’ll carry every day, you want something tough and corrosion-resistant. Stainless steel like 440C or VG-10 is often a good choice. It can handle daily tasks and won’t rust easily if it gets wet.

2. Kitchen Knives

Kitchen knives need to be very sharp and hold that sharpness. Carbon steels like 1095 or certain stainless steels like VG-10 are excellent. They can be honed to a fine edge. Remember that carbon steel needs careful cleaning and drying after use.

3. Outdoor and Survival Knives

Knives for outdoor use need to be tough and able to withstand hard work. Carbon steels like O1 tool steel or tough stainless steels like D2 are often used. They can handle chopping, prying, and other demanding tasks.

Frequently Asked Questions (FAQ) About Knife Making Metal

Q1: What is the best metal for a beginner knife maker?

A1: For beginners, 1075 or 1095 carbon steel is often recommended. It’s easier to heat treat and sharpen than many stainless steels.

Q2: Does stainless steel rust?

A2: While “stainless” steel resists rust much better than carbon steel, it can still corrode under certain conditions, especially if exposed to salt or harsh chemicals for long periods.

Q3: How does heat treatment affect a knife’s performance?

A3: Proper heat treatment makes the metal harder and tougher. This allows the knife to hold a sharp edge longer and resist chipping or breaking during use.

Q4: Can I use any old piece of metal to make a knife?

A4: No, you should use metal specifically made for knife making. These steels have the right composition and are designed to be heat-treated effectively.

Q5: What is the difference between carbon steel and stainless steel?

A5: The main difference is the chromium content. Stainless steel has more chromium, which makes it resistant to rust. Carbon steel has more carbon, which makes it harder and easier to sharpen.

Q6: How do I prevent my carbon steel knife from rusting?

A6: You should clean and dry your carbon steel knife immediately after use. Applying a light coat of food-safe mineral oil or wax will also protect it from moisture.

Q7: What does ” Rockwell hardness” mean?

A7: Rockwell hardness is a scale used to measure how hard a metal is. A higher Rockwell number usually means the metal is harder and can hold an edge better.

Q8: Is D2 steel a good choice for a knife?

A8: D2 is a semi-stainless tool steel. It’s very hard and holds an edge well, but it’s not as corrosion-resistant as some other stainless steels. It can be a bit tougher to sharpen.

Q9: How important is the carbon content in knife steel?

A9: Carbon content is very important. More carbon generally means the steel can be made harder and hold a sharper edge. However, too much carbon can make the steel brittle.

Q10: Where can I buy knife making metal?

A10: Knife making metal can be purchased from specialized knife supply companies, metal suppliers, and online retailers that cater to hobbyists and professional bladesmiths.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Scott Fischer, the voice behind SliceItRight. My passion for food started in my grandmother’s kitchen, where I learned the art of slicing, dicing, and creating delicious meals. Over the years, I’ve explored everything from the perfect kitchen gadgets to mastering culinary techniques, and I’m here to share all of it with you. Whether you’re a beginner or an experienced home chef, my goal is to make cooking easier, more enjoyable, and a lot more fun. So, let’s slice it right and cook up something amazing together!