Have you ever felt lost in a sea of steel types, trying to figure out which one is best for your dream knife? Choosing the right steel can feel like a daunting task with so many options and confusing technical terms. You want a blade that holds an edge, resists rust, and can handle the tasks you throw at it, but where do you even start?

Picking the wrong steel can lead to a knife that dulls quickly, chips easily, or even rusts, turning your passion project into a frustrating experience. That’s why understanding the basics of knife steel is so important. It’s the difference between a tool you cherish and one that sits unused in a drawer.

This guide is here to cut through the confusion. We’ll explore different types of knife steel, explain their strengths and weaknesses, and help you understand what makes each one unique. By the end, you’ll have the knowledge to confidently select the perfect steel for your next knife-making adventure. Let’s dive in and discover the fascinating world of knife steel!

Our Top 5 Knife Making Steel Recommendations at a Glance

Top 5 Knife Making Steel Detailed Reviews

1. 4 Pack 1084 Steel for Knife Making-12 x1.5 x1/8″ Steel Flat Stock

Rating: 9.3/10

This 4 Pack of 1084 Steel Flat Stock is designed for knife making and general fabrication. The steel comes in convenient 12″ x 1.5″ x 1/8″ flat bars, making it easy to work with. This pack gives you four pieces of steel to start your projects. It is made for both beginners and experienced crafters who need reliable steel.

What We Like:

- The steel is cold rolled and annealed. This makes it easier to machine and improves its performance. You save time and effort.

- The 1084 steel has a moderate carbon content. This means it is strong but not too brittle. It works well for many uses.

- The flat steel is versatile. You can cut it, bend it, machine it, or form it into different shapes. The square edges are easy to hold.

- The packaging is very protective. It includes rustproof oil, paper, bubble wrap, and a cardboard box. This prevents rust and damage during shipping.

What Could Be Improved:

- Some users might prefer a wider selection of sizes in the pack.

- More information on heat treating is not included. Beginners might need to research this separately.

Overall, this 4 Pack of 1084 Steel Flat Stock is a great value for knife makers and metalworkers. The protective packaging and ease of use make it a solid choice.

2. 5 Pack 1095 Steel for Knife Making – 12″x2″x0.12″ Annealed High Carbon Tool Steel Blanks

Rating: 8.8/10

This 5-pack of 1095 Steel for Knife Making offers high-quality, annealed high carbon tool steel blanks. Each piece measures 12″x2″x0.12″, making them ideal for crafting durable knife blades and tackling various DIY projects. The steel is precision ground and comes ready for you to shape and customize.

What We Like:

- Excellent Steel Choice: The 1095 steel is a top pick for knife makers. It’s known for its toughness and how well it grinds, making it great for handmade knives.

- Easy to Work With: The steel is annealed, which means it’s been treated to be easier to machine. You can shape it without wearing out your tools.

- Good Size and Quantity: Each pack has five steel bars. The size (12″ x 2″ x 0.12″) gives you enough material to make several knives or a larger project.

- Protective Packaging: The steel comes in three layers of protection to prevent rust and damage during shipping. This ensures you get the steel in top condition.

- Customer Satisfaction: The company stands behind its product. If you’re not happy, they will work to make it right.

What Could Be Improved:

- Slightly Thinner Size: Although the thickness is good for many knives, some makers might prefer a slightly thicker option for larger blades.

This 1095 steel is a fantastic choice for both beginner and experienced knife makers. It’s ready for your creative touch to make a long lasting knife.

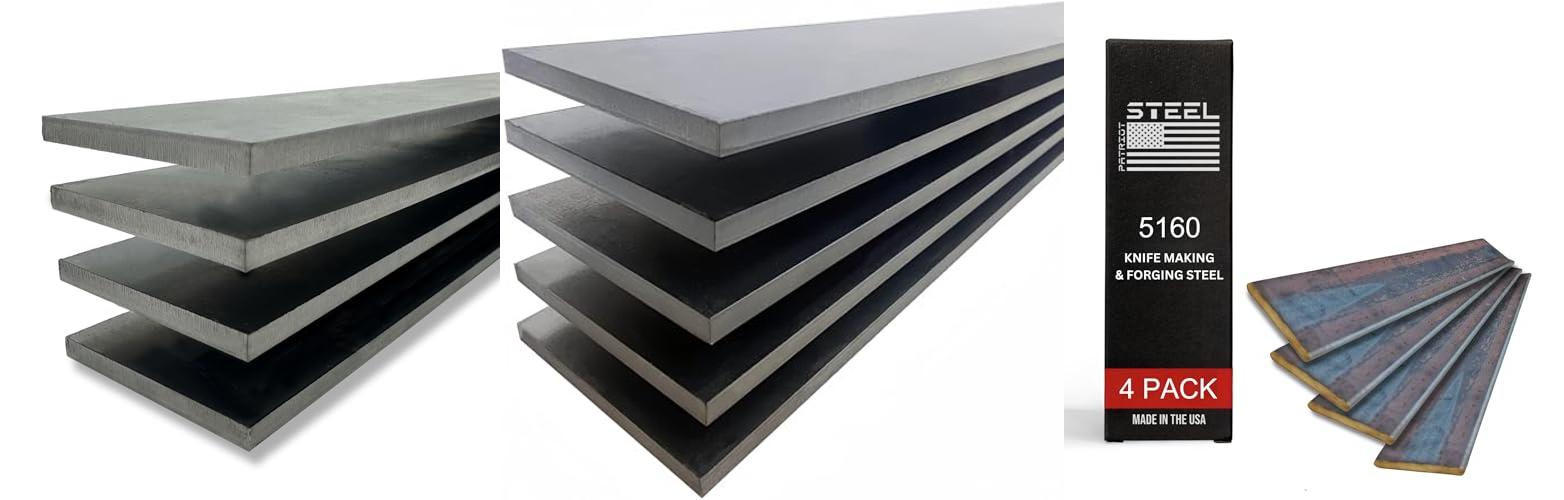

3. Patriot Steel 5160 High Carbon Knife Making & Forging Steel – Hot Rolled Steel for Knife Making Supplies – USA-Milled Excellence for Pros & Hobbyists – 1.25″ wide

Rating: 9.3/10

The Patriot Steel 5160 High Carbon Knife Making Steel is a great choice for anyone who wants to make knives. This pack includes four pieces of hot-rolled steel, each milled in the USA. The steel is 1.25″ wide, 0.25″ thick, and 12″ long, providing ample material for various knife designs. Whether you are a professional or a hobbyist, this steel is made to meet your needs.

What We Like:

- Exceptional Quality: The 5160 steel is crafted in the USA and meets high quality standards. This ensures great performance for your knife projects.

- Reliable Consistency: Small batch production and inspections mean you get a consistent product every time. This is good for knife making and other steel work.

- Versatile for All Skill Levels: This high carbon steel is ideal for both professionals and hobbyists. It works well for any knife making project.

- American Made: Patriot Steel manufactures all its products in the USA. You can trust the quality and authenticity of this steel.

What Could Be Improved:

- Size Options: While the 12″ length is useful, offering a wider range of lengths could cater to more diverse projects.

- Surface Finish: Though hot-rolled steel is standard, providing an option for pre-ground or polished surfaces could save time for some users.

In conclusion, Patriot Steel 5160 High Carbon Steel is a reliable and high-quality option for knife making. It is made in the USA and is perfect for any knife maker.

4. Amyhill 6 Pack 1084 Steel for Knife Making – 1/8″ x 1-1/2″ x 12″ Flat Stock for Hobbyist and Professional Use

Rating: 8.7/10

The Amyhill 6 Pack 1084 Steel is great for anyone who wants to make knives. The pack has six flat steel bars. They are coated with oil to keep them from rusting. You can use these to make all kinds of knives. They work for both beginners and experts.

What We Like:

- You get six steel bars in one package. This is enough for many projects.

- The 1084 steel is high carbon. This makes it good for cutting tools.

- The steel is smooth and doesn’t rust easily.

- The size is good for making different kinds of knives.

- It is easy to work with. You can heat treat and cut it easily.

- You can use it for practice or for making real tools.

What Could Be Improved:

- The size may be slightly off due to manual measurement.

- The slushing oil can be messy. You will need to clean it off before use.

In conclusion, this steel is a good choice for knife making projects. It offers a good balance of quality and ease of use for both hobbyists and professionals.

5. Patriot Steel 1095 High Carbon Knife Making & Forging Steel – Cold Rolled Annealed Flat Bars & Blanks – Knifemakers

Rating: 8.9/10

The Patriot Steel 1095 High Carbon Knife Making Steel is a great choice for anyone who wants to make knives. These flat bars are made in the USA from 1095 high carbon steel. They are perfect for forging, heat treating, and bladesmithing. The steel is cold rolled annealed, which means it is easy to work with. This saves you time and effort when shaping your blades.

What We Like:

- USA-milled 1095 high carbon steel provides consistent quality and performance.

- Cold Rolled Annealed (CRA) steel reduces prep time, making it easier to shape blades.

- Ideal for bladesmithing and forging, suitable for beginners and professionals.

- Consistent dimensions and hardness ensure reliable results every time.

- Dependable supply for knifemakers, backed by American craftsmanship.

What Could Be Improved:

- The 12″ length might be too short for some larger knife projects.

- The 0.125″ thickness might require more material removal for certain blade designs.

- Rusting can occur if the steel is not properly oiled or treated.

If you are looking for a reliable and consistent steel for your knife making projects, the Patriot Steel 1095 is a good option. It provides a solid foundation for creating high-quality blades.

The Ultimate Buying Guide: Forging Your Own Legend – Knife Making Steel

So, you want to make your own knife? That’s awesome! But before you start hammering away, you need to pick the right steel. This guide will help you choose the best knife making steel for your project, whether you’re a beginner or a seasoned pro.

Key Features to Look For

Think about what you want your knife to do. Different steels are good at different things. Here are some key features to consider:

- Hardness: Hard steel can hold an edge really well. It’s measured using Rockwell C (HRC). Higher HRC means harder steel.

- Toughness: Tough steel can take a beating without breaking. It resists chipping and cracking.

- Wear Resistance: Steel with good wear resistance stays sharp longer even with lots of use. It resists abrasion.

- Corrosion Resistance: This is how well the steel resists rust and stains. Stainless steels are known for this.

- Ease of Sharpening: Some steels are easier to sharpen than others. Really hard steels can be tough to get a good edge on.

Important Materials: The Steel Lineup

Lots of different steels are used for knife making. Here are a few popular choices:

- 1095 High Carbon Steel: This is a classic. It’s relatively inexpensive, easy to work with, and takes a great edge. It can rust easily, so you need to take care of it.

- O1 Tool Steel: Another popular choice for beginners. It’s tough, holds an edge well, and is easier to sharpen than some stainless steels. It also needs to be protected from rust.

- D2 Tool Steel: This steel is a good balance of hardness, toughness, and wear resistance. It’s considered a semi-stainless steel.

- 440C Stainless Steel: A common stainless steel for knives. It’s corrosion resistant and holds an edge reasonably well.

- AEB-L Stainless Steel: A popular high-performance stainless steel. It’s known for its fine grain and ability to take a very sharp edge.

- CPM S35VN Stainless Steel: A modern, high-end stainless steel. It has excellent hardness, toughness, and wear resistance.

Factors That Improve or Reduce Quality

The quality of knife making steel depends on several things:

- Heat Treatment: This is crucial. Proper heat treatment gives the steel its hardness, toughness, and other desired properties. Poor heat treatment can ruin even the best steel.

- Steel Composition: The specific mix of elements in the steel affects its properties. More carbon generally means harder steel. Chromium makes steel stainless.

- Manufacturing Process: How the steel is made can influence its quality. Powder metallurgy (like CPM steels) often results in a finer grain structure and better performance.

- Thickness: Thicker steel can make a stronger, more durable blade.

- Surface Finish: A smooth, even surface finish is important for both aesthetics and performance.

User Experience and Use Cases

Think about how you will use the knife. A chef’s knife needs to be different than a hunting knife.

- Chef’s Knives: You want something that holds a sharp edge and is easy to sharpen. Stainless steel is good for corrosion resistance in the kitchen.

- Hunting Knives: You need something tough and durable that can withstand hard use. High carbon steel or a tough tool steel might be a good choice.

- Everyday Carry (EDC) Knives: You want something that’s easy to carry, holds an edge well, and resists rust. Stainless steel is a popular choice.

- Beginner Knife Makers: Start with easier-to-work-with steels like 1095 or O1. These steels are more forgiving and easier to heat treat.

Frequently Asked Questions (FAQ)

Q: What HRC should my knife steel be?

A: It depends on the steel and the intended use. Generally, knife steel ranges from 55-65 HRC. Higher HRC means harder steel, but it can also be more brittle.

Q: What is the best steel for a beginner?

A: 1095 high carbon steel and O1 tool steel are good choices for beginners. They are relatively inexpensive and easier to work with.

Q: How do I heat treat knife steel?

A: Heat treating is a complex process that involves heating the steel to a specific temperature and then cooling it in a controlled manner. You will need a forge or kiln, and it’s best to follow specific instructions for the steel you are using. Consider sending it to a professional for heat treatment.

Q: What does “stainless steel” mean?

A: Stainless steel contains chromium, which makes it resistant to rust and stains. It’s not *stain-proof*, but it’s much more resistant to corrosion than carbon steel.

Q: Can I use any steel to make a knife?

A: No. You need to use steel specifically designed for knife making. It needs to be hardenable and have the right properties for holding an edge.

Q: What is the difference between carbon steel and stainless steel?

A: Carbon steel contains a higher percentage of carbon than stainless steel. This makes it harder and able to take a sharper edge, but it also makes it more prone to rust. Stainless steel is more corrosion resistant but may not get as sharp as carbon steel.

Q: Where can I buy knife making steel?

A: You can buy knife making steel from online retailers that specialize in knife making supplies. Search for terms like “knife making steel suppliers” or “knife steel blanks.”

Q: What tools do I need to make a knife?

A: You’ll need a forge or kiln for heat treating, an anvil, hammers, files, a grinder, and safety equipment like gloves and eye protection. It’s a good idea to start with a simple project and gradually acquire more tools as your skills improve.

Q: How do I prevent my carbon steel knife from rusting?

A: Keep it clean and dry. Apply a thin coat of oil to the blade after each use. Store it in a dry place.

Q: What is “edge retention?”

A: Edge retention refers to how long a knife stays sharp with use. Steels with good wear resistance have good edge retention.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Scott Fischer, the voice behind SliceItRight. My passion for food started in my grandmother’s kitchen, where I learned the art of slicing, dicing, and creating delicious meals. Over the years, I’ve explored everything from the perfect kitchen gadgets to mastering culinary techniques, and I’m here to share all of it with you. Whether you’re a beginner or an experienced home chef, my goal is to make cooking easier, more enjoyable, and a lot more fun. So, let’s slice it right and cook up something amazing together!